Loading

Loading

A Legacy

of Quality

and Territory

On the ridge of the Paderno plateau—where Leonardo da Vinci, enchanted by the beauty of the landscape, found inspiration for the backdrops of his paintings—the first electrically powered mill was built in 1882.

In the early 1900s, Federico Wyttenbach passed the torch to the Colombo family, who transformed the mill into a modern industrial reality. Over the decades, Molino Colombo flour became a symbol of excellence.

Today, after more than a century of quality and craftsmanship, Molino Colombo remains a benchmark for those who see excellence as their ultimate goal.

To stay at the forefront of a highly competitive market, we rely on: the finest wheat varieties, advanced milling technologies and a deep-rooted milling tradition that combines cutting-edge equipment with the expertise of generations.

This perfect balance is what makes Colombo flour unique.

State-of-the-Art

Milling Facilities

A key secret behind our quality is our unique production cycle, which prioritizes quality over maximizing output.

Our ultramodern production facility blends the latest technological advancements with the highest values of artisanal craftsmanship, using a one-of-a-kind extended milling diagram.

Why Our Milling Process is Different

Selecting

the finest

raw materials

The excellence of Molino Colombo flour starts with a meticulous selection of the best raw materials.

Our sourcing process is continuous and rigorous, ensuring that we choose only the finest wheat varieties, carefully selected based on the intended use of our flours.

Since Italian wheat production only covers 40% of the total demand of the Italian milling industry, we carefully source high-protein wheats from the EU and non-EU countries to meet the exceptionally high standards of Italian pastry-making (Panettone and other large-leavened products).

Soltanto il meglio dei grani Italiani viene selezionato per le nostre miscele, ma bisogna tenere conto che la produzione di grano Italiano copre solo il 40% di ciò che viene macinato dall’industria molitoria italiana; inoltre per alcune specialità della pasticceria Italiana (Panettone e lievitati in genere) sono necessari grani ad alto contenuto proteico selezionati tra i migliori grani della Comunità Europea ed EXTRA EU per soddisfare gli altissimi standard della pasticceria italiana.

Research

& Development

Molino Colombo’s R&D division is another key differentiator.

Our in-house expertise allows us to develop innovative products, including:

Semi-finished mixes, Flour improvers and Custom flour solutions tailored to specific customer needs

By offering high-value consulting, we help our clients optimize their production and develop unique, high-performance products.

Uncompromising

Quality Control

To ensure the highest standards, every batch of incoming wheat and finished flour undergoes rigorous laboratory testing, including:

Rheological tests (Farinograph, Extensograph, Chopin), Chemical-physical analysis (Moisture, Protein, Gluten, Falling Number, Amylogram), Dough fermentation tests (Reofermentograph)

But We Go Even Further

Each flour batch is tested to ensure the absence of over 150 contaminants, including glyphosate.

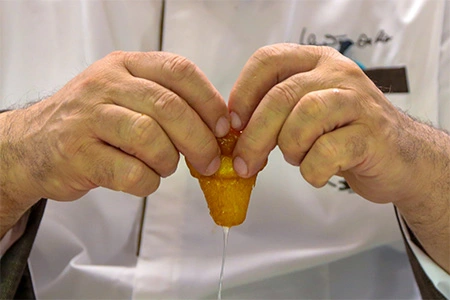

Also every flour is tested in our Accademia della Farina, ensuring not only technical excellence but also creativity in application for our customers.

At Molino Colombo, quality is not just a promise—it’s a daily commitment to excellence.